What is a wire bonding machine?

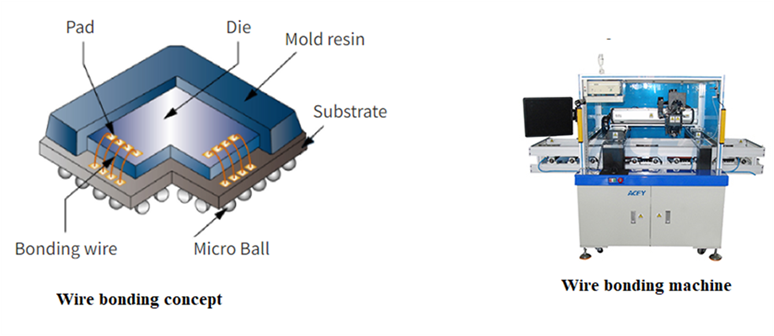

A wire bonding machine (also called a wire bonder) is specialized equipment used to perform wire bonding in the semiconductor device manufacturing industry. The bonding process utilizes fine wires, typically made of gold, aluminum, copper, or silver, to connect bond pads on the die (IC) to the leads of the package, creating electrical connections between the die and its packaging. The wire diameter typically ranges from 8 μm up to several hundred micrometers, e.g., 500 μm for high-powered applications. Wire bonding is essential for ensuring reliable signal transmission and power distribution within the device, as well as ensuring the device's reliable performance.

Figure 1: Wire bonding concept and wire bonding machine shown

Figure 1: Wire bonding concept and wire bonding machine shown

Ball bonding and wedge bonding are the two main categories of wire bonding. Typically, wire bonding machines are designed to perform either ball bonding or wedge bonding due to the different processes and tools involved. However, some machines are available to perform both types of bonding; they usually require significant reconfiguration and different tooling. Modern wire bonding machines mostly utilize ultrasonic energy, pressure, temperature, and time (i.e., Thermosonic method) for the bonding process. The machine may also use the Thermo-compression Method or Ultrasonic Method.

Key components:

The key components of a thermosonic-based wire bonder machine include an ultrasonic generator, bonding tools (capillary or wedge tools), a work table (to place the semiconductor chip), a wire feeder (to feed wires), a heating system, a clamping system, a positioning system (to position the bonding tool), a control system, and other supporting systems.

How does a wire bonding machine work?

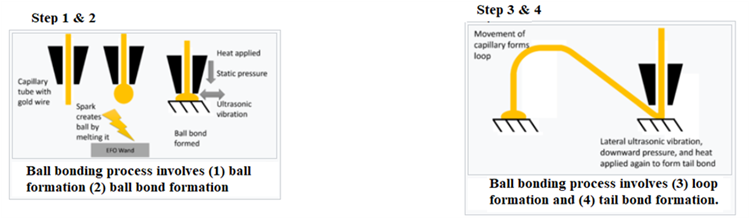

Ball bonding: In this bonding process, the wire bonder machine uses a capillary tool (fed with wire) to form a ball at the wire tip by applying an electrical spark. Then, the machine moves down the tool vertically, places the ball on a bond pad on the die, and applies pressure, heat, and ultrasonic energy for a certain period. This process forms a metallurgical bonding (first bond) between the wire and the pad. Then, the machine moves the capillary tool to the target pad (lead frame) on the package substrate, forming a loop.

Figure: Ball bonding process

Figure: Ball bonding process

Now, the machine moves down the tool, places the wire on the target pad (or lead frame), and applies pressure, heat, and ultrasonic energy for a certain period to create a second bond. The second bond is called the wedge bond (tail bond), which is formed without ball formation. After creating the second bond, the machine lifts the bonding tool and breaks or cuts the wire to get ready for the next wire bonding. The ball bonding process is fast and commonly used with gold and copper wires, ideal for die-to-lead frame connections.

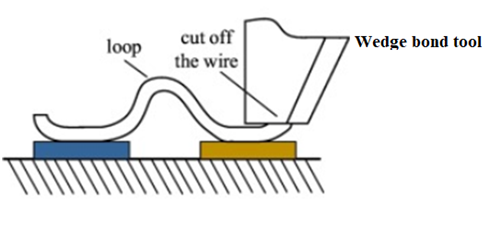

Wedge bonding: In this bonding process, the wire bonding machine uses a wedge tool to press the wire onto the die pad and applies ultrasonic and/or thermal energy. This process creates a first wedge bond between the wire and pad. This bonding technique works without creating a ball. Next, the machine moves the tool to the target pad on the package substrate, forming a loop, and follows the same bonding procedure used in the first wedge bond creation to create a second wedge bond. After creating the second bond, the machine lifts the bonding tool and breaks or cuts the wire to get ready for the next wire bonding.

Figure: Wedge bonding

Figure: Wedge bonding

The wedge bonding process is generally used with gold and aluminum wires and is ideal for small bond pads and high-frequency applications. This bonding process supports the use of ribbon-shaped wires for high-power interconnects. Note that it is slow process as compared to ball bonding.

Applications:

Wire bonding machines are used to perform wire bonding process for a variety of semiconductor devices, including MEMS sensors, memory chips, microprocessors, accelerometers, power devices like MOSFETs and IGBTs, optoelectronics such as LED chips, Bluetooth/WiFi radiofrequency devices, multi-chip modules (MCMs), etc.

They come in manual, semi-automatic, and fully automatic versions and can support different modes (i.e., ball bonding/wedge bonding, or both). These machines can be integrated into the semiconductor device production lines.